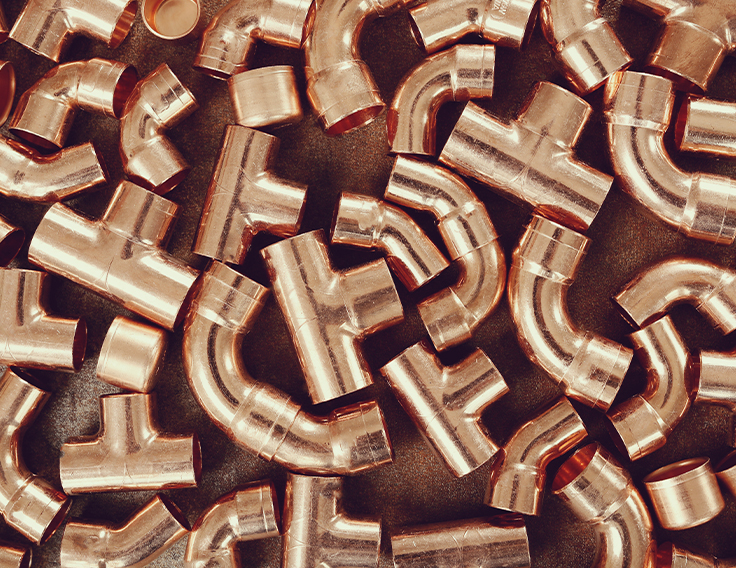

Water hardware

Sealing transparent paint

Waterborne electroplating clear paint (self-drying)

It is made of water-based acrylic resin and excellent anti-corrosion formula to develop gloss and adhesion for electroplating materials. It can be applied to various metal materials. Zinc alloy, aluminum alloy, magnesium alloy, stainless steel, iron, and copper metal finish.

Through the research and development of a professional team, Xinfa Coatings has developed a series of coating types that meet the needs of customers, including:

(1) Introduction to water-based clear paint (varnish, lacquer, varnish, varnish)

(2) Water-based flat paint ( Matte paint, matt paint, fog paint), (color fine)

(3) Paint remover (paint stripper, paint remover)

Water-based alkyd amino baking paint:

The alkyd amino baking varnish is prepared with water-based alkyd resin and amino resin as the main body, and it is cured into a film by the cross-linking reaction of water-based alkyd resin and amino resin at a certain temperature. The water-based alkyd amino baking varnish has good gloss and bright colors. Degree, film hardness, toughness.

Water-based acrylic amino baking paint:

The water-based acrylic amino baking paint is designed with water-based acrylic resin and amino resin as the main body. It is cured into a film through the cross-linking reaction of acrylic resin and amino resin at a certain temperature. It has excellent adhesion to different metals and is very resistant to salt spray. Well, it is an important industrial coating.

advantage:

(1) Low pollution to air pollution

(2) Resource-saving paint because it uses water as the main solvent

(3) The painting environment is safe and sanitary

(4) The fire hazard is low

(5) Existing painting equipment, Can be used without large-scale modification

Physical organization:

(1) It is not easy to evaporate and has a low boiling point; the coating is easy to foam and sag.

(2) When the humidity is high, the evaporation rate is very slow, and there is almost no evaporation above 80%.

(3) The surface tension is high, 2.5 times that of the solvent: Poor wettability between materials or layers

(4) High conductivity: The electrostatic coating machine must be improved

※Viscosity cup (25℃)

★Suitable for electrostatic spraying, air spraying and dip coating.

★The transparent paint can be made into matting paint with different gloss (flat paint, matt paint) and various bright color paints by adding matting powder, or color masterbatch and color essence.

★Please stir evenly before using the flat paint.

A consumption tax on solvent-based coatings will be levied on February 1, 2015.

Coatings with a content of less than 420 g/L (inclusive) are exempt from consumption tax, and water-based technology is one of the most effective ways to reduce the VOC emissions of coatings.