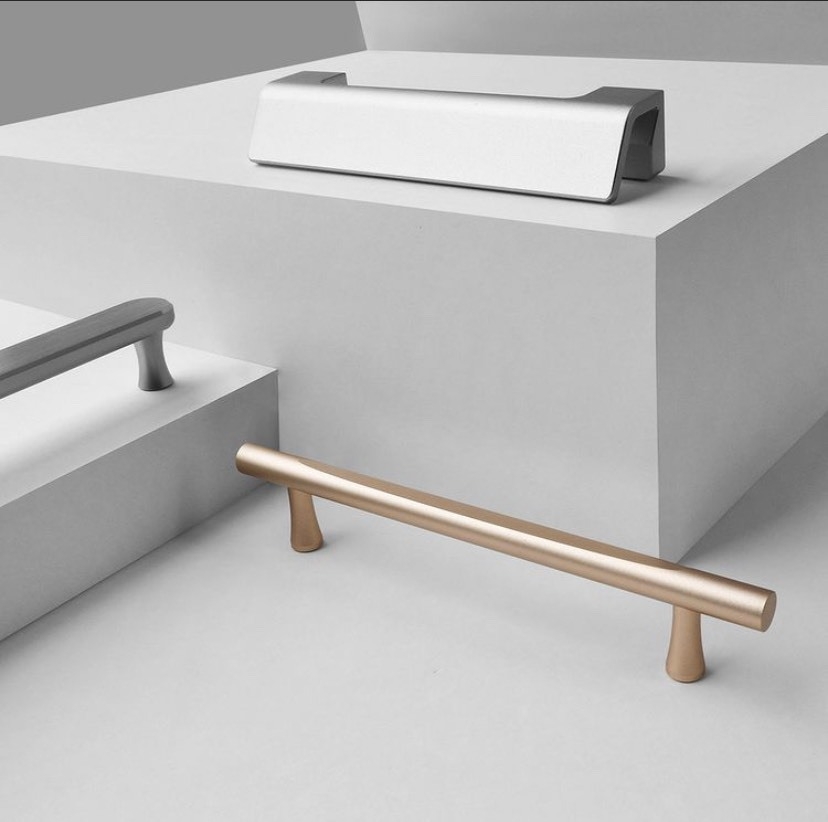

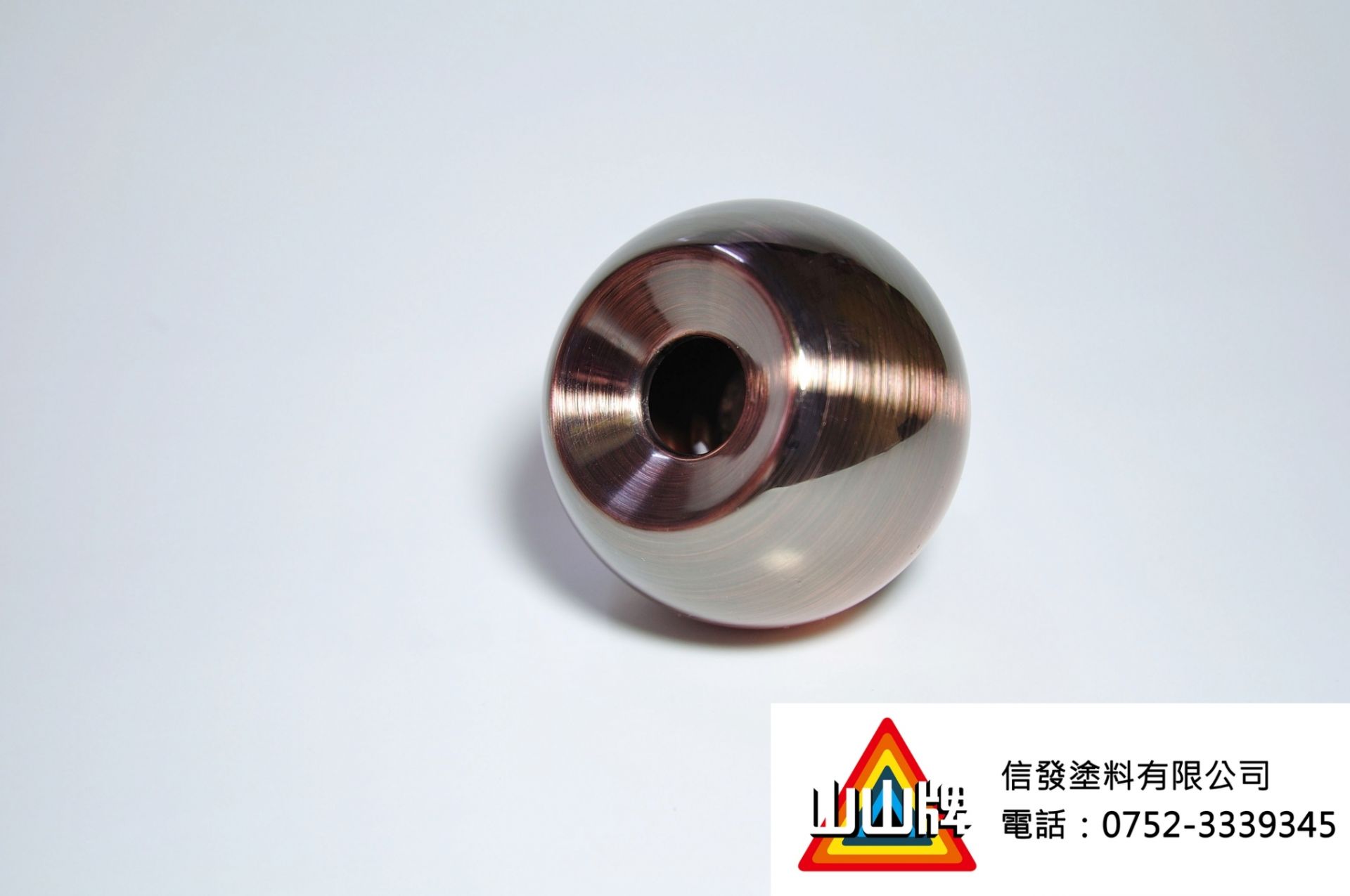

Door lock hardware

Artificial sweat resistant transparent paint

NT$0

NT$0

The main purpose

Paint processing, door control hardware, curtain hardware, screws, furniture hardware, hand tools, shoe hardware, lamps, door and window railings, landscape modeling, advertising building materials, metal parts, hardware accessories, machine tools, hand tool hammers, hand tool axes. Stainless steel primary color art carved doors, sports equipment, gardening hardware, aluminum building materials, bathroom faucets

Oily electroplating transparent baking varnish (baking varnish) Product introduction

Tailored design according to the customer's coating process: products with different spray conditions can be provided with one coating and one baking, two coating and two baking, or three coating and three baking.

| Product name | Main agent: the paint system does not need thinner: use directly |

|

| The mixing ratio | 1 | |

| Filter screen | Screen with 200-300 mesh | |

| Spray gun, air pressure | 3~4 kgf/cm² | |

| Coating film thickness | Electroplating transparent paint 10-25um | |

| Complete drying time | 110°-180°×40 minutes | |

| Packing condition | The material can be packaged after cooling | |

| Physical test conditions | 1. The normal test conditions are 150℃×20min, and the physical properties can be tested after confirming the material and film cooling after standing for 1~2 hours. 2. The simulated environment test condition is 150℃×20min, and the simulated environment test can be carried out after standing for 24 hours. |

|

| Applicable material | Various metal materials. Zinc alloy. Aluminum alloy. Magnesium alloy. Stainless steel. Iron. Copper | |

Product physical properties table (the following is the test of zinc alloy + electroplating nickel + 2020 electroplating clear paint)

| Test items | Test Conditions | Test Results | |

| 1 | Attach | Place the coated object at a level and draw a knife across the solid with a 100-grid knife. After cleaning the damaged area, stick the 100-grid area with 3M#610 tape, and pull it at a 45° angle for three times . There is no abnormality in the 100-grid. | No abnormality. No paint film falling |

| 2 | hardness | Place the tested board horizontally with pencil hardness <Mitsubishi Pencil>, load 500g, hardness 3H, no scratches on the coating surface | No scratches |

| 3 | Film thickness | Measured by film thickness meter | Electroplating clear paint: 10-25um |

| 4 | Flexibility | Flexibility ≤2mm without cracks | No cracks |

| 5 | Impact test | φ1/2×500g×30cm without paint stripping | No paint stripping |

| 6 | Gloss | Measured by 60° gloss meter, more than 97% gold oil | More than 97% |

| 7 | Cupping test | Cup convexity testing machine | ≤6mm without cracks |

| 8 | High pressure water rush test | Use a water gun with a pressure of 80-100bar to spray the painted film with a distance of 2-3cm, and the time is 3-4 minutes |

100% of the coating film surface does not fall off |

| 9 | RCA resistance | Load 175g and rub the film with paper tape 30 times without exposed substrate (lacquer) | No change in appearance |

| 10 | Water resistance | After immersing in pure water at 40±2℃ for 240h, after taking it out and letting it stand for 1h, there is no softening, discoloration, blistering, adhesion drop, etc. | No change in appearance |

| 11 | Stain resistance | Temperature 35℃, humidity 95%, 5% NACL solution spray, experiment time: after 720H in the salt spray environment, the surface of the product has no rust or discoloration | Single side rot <2mm attached OK |

| 12 | Acid resistance | After soaking in 10% sulfuric acid for 24 hours at 20±2℃, the coating film has no obvious softening, discoloration, blistering, adhesion drop, etc. | No change in appearance |

| 13 | Salt spray resistant | After 20±2℃, 10% sodium chloride for 120H, the coating film has no obvious softening, discoloration, blistering, adhesion drop, etc. | No abnormal appearance |

| 14 | Humidity test | Gold oil: the temperature is 65℃, the humidity is 90%, and the performance remains unchanged after 24 hours. | No abnormal appearance |

| 15 | Resistance to cold and hot loops | ―40℃×1.5H→25℃×0.5H→65℃/RH90%×1.5H is a cycle, do 20 loops | No abnormal appearance |

| 16 | Oil resistance | 0±2℃, soaking in automobile engine lubricating oil for 1 hour, after washing for 1 hour, the coating film has no obvious softening, discoloration, blistering, adhesion drop, etc. | No abnormal appearance |

| 17 | Gasoline resistance | 20±2℃, gasoline soaked for 1 hour, after washing for 1 hour, the coating film has no obvious softening, discoloration, blistering, adhesion drop, etc. | No abnormal appearance |